Unpacking Carbon Capture and Storage Technology

What Is Carbon Capture and Storage?

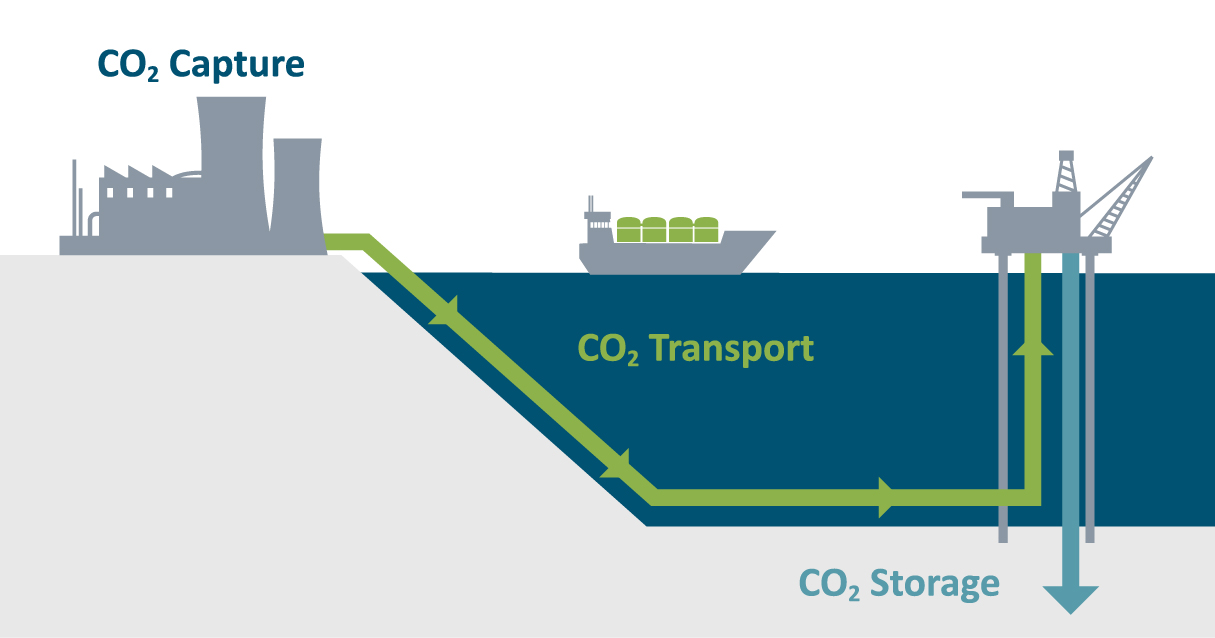

Carbon capture and storage (CCS) is a multifaceted process that captures carbon dioxide emissions from industrial activities or power plants before they enter the atmosphere. The captured CO2 is then transported to a designated site where it is either permanently stored underground or repurposed for industrial use.

This technology is divided into three key stages:

-

Capture: Extracting CO2 from industrial processes or power generation.

-

Transport: Moving the captured CO2 via pipelines, ships, or trucks to storage or utilization sites.

-

Storage/Utilization: Either securely sequestering the CO2 in geological formations or using it in applications like enhanced oil recovery or the production of materials such as concrete.

CCS plays a critical role in the global push to reduce greenhouse gas emissions, particularly for hard-to-abate sectors like cement, steel, and chemical manufacturing, where alternatives to fossil fuels are limited.

The Role of Carbon Capture Utilization and Storage

From Waste to Resource: The Utilization of Captured Carbon

Carbon capture utilization and storage (CCUS) represents a significant evolution in the way we think about managing carbon emissions. Rather than merely sequestering carbon dioxide (CO2) underground, CCUS transforms this greenhouse gas into valuable products, turning a waste material into a resource for industries. This approach not only contributes to emission reduction efforts but also creates economic opportunities, highlighting the dual benefits of CCUS.

Enhanced Oil Recovery (EOR)

One of the most established applications of captured CO2 is in enhanced oil recovery (EOR). In this process, CO2 is injected into depleted oil reservoirs to increase oil extraction. The injection of CO2 helps to lower the viscosity of the oil, making it easier to pump out of the ground. This method not only extends the life of oil fields but also sequesters CO2 underground, effectively reducing atmospheric emissions.

EOR has been successfully implemented in various regions, demonstrating the economic viability of using captured CO2 in the oil industry. By enhancing oil production, EOR provides a financial incentive for industries to invest in CO2 capture technologies, thereby promoting the broader adoption of CCUS practices.

Building Materials

The construction industry offers another promising avenue for the utilization of captured CO2. CO2 can be used in the production of building materials, such as concrete, by being integrated into the curing process. This not only helps to reduce the carbon footprint of concrete production but also enhances the strength and durability of the material.

In addition to concrete, CO2 is being explored as a raw material for producing carbon-neutral fuels and polymers. By converting CO2 into synthetic fuels, industries can create sustainable energy sources that help to close the carbon loop. Similarly, CO2-derived polymers can be used in various applications, from packaging to automotive parts, contributing to the development of sustainable products.

Agriculture

In the agricultural sector, captured CO2 can be converted into fertilizers or used in the cultivation of algae-based biofuels. The use of CO2 in algae cultivation is particularly promising, as algae can efficiently absorb CO2 and convert it into biomass. This biomass can then be processed into biofuels, providing a renewable energy source that further reduces greenhouse gas emissions.

The transformation of CO2 into fertilizers also holds potential for improving agricultural productivity. By enriching the growth environment with CO2, crops can achieve higher yields, contributing to food security while simultaneously reducing carbon emissions.

Creating Circular Economies

The shift from mere storage to utilization reflects a broader trend in carbon management towards creating circular economies. By repurposing CO2 emissions as valuable inputs for industrial processes, CCUS helps to close the loop on carbon emissions, turning what was once a waste product into a driver of economic growth.

This approach aligns with global sustainability goals by promoting resource efficiency and reducing dependence on fossil fuels. As CCUS technologies continue to advance, they offer a scalable solution for industries seeking to balance economic and environmental objectives, paving the way for a more sustainable future.

The Economics of Carbon Capture and Storage

Profitability and Challenges

Carbon capture and storage (CCS) has immense potential to mitigate climate change, but its economic feasibility remains one of the primary obstacles to widespread adoption. The costs of developing, deploying, and maintaining CCS systems are significant, often deterring industries from investing in the technology. While CCS offers environmental benefits, profitability is a major concern that must be addressed for large-scale implementation.

Cost Drivers in CCS

-

Capture Costs: The capture phase is the most expensive stage of CCS, accounting for up to 70% of total costs. Separating CO2 from industrial emissions requires energy-intensive processes, such as chemical absorption or membrane filtration, which drive operational costs higher.

-

Transportation Costs: Once captured, CO2 must be transported to storage or utilization sites, often via pipelines, ships, or trucks. Building this infrastructure, especially over long distances, can be costly and logistically challenging.

-

Storage Costs: Long-term storage of CO2 requires continuous monitoring and maintenance of underground sites, such as saline aquifers or depleted oil fields, to ensure safety and prevent leaks. These additional operational costs contribute to the financial burden.

Making CCS Profitable

Profitability for CCS hinges on external support and market opportunities. Government incentives, such as tax credits for carbon storage or subsidies for CCS infrastructure, play a vital role in reducing upfront costs. Carbon pricing mechanisms, including carbon taxes or emissions trading schemes, can further incentivize companies to invest in CCS by monetizing emission reductions.

Additionally, advancements in carbon utilization, such as turning CO2 into building materials or fuels, offer new revenue streams for captured carbon. The growing demand for green technologies in construction, agriculture, and energy sectors provides opportunities for industries to offset CCS costs and achieve economic viability.

The Rise of Carbon Capture and Storage Clusters

Collaborative Carbon Management

To scale CCS efficiently, the concept of carbon capture and storage clusters has emerged. CCS clusters involve a network of facilities and industries working together to capture, transport, and store CO2. These clusters often share infrastructure, such as pipelines or storage reservoirs, reducing costs and enabling economies of scale.

Key Features of CCS Clusters

-

Shared Infrastructure: Reduces the financial burden on individual facilities by spreading costs across multiple stakeholders.

-

Proximity to Geological Storage: Many clusters are located near natural geological formations suitable for CO2 storage, such as saline aquifers or depleted oil fields.

-

Supportive Policies: Governments often back CCS clusters with funding, tax incentives, or regulatory frameworks to encourage collaboration.

Examples of successful CCS clusters include Norway’s Northern Lights project and the UK’s Humber Cluster. These initiatives demonstrate how shared infrastructure and collaboration can accelerate the deployment of CCS technologies while lowering costs.

Carbon Sequestration Technology: How It Works

Turning CO2 Into a Permanent Solution

At the heart of CCS lies carbon sequestration technology, which ensures the permanent storage of CO2 in geological formations. Once captured and transported, CO2 is injected deep underground into reservoirs such as saline aquifers or depleted oil and gas fields. Here, it is trapped securely through physical and chemical processes.

Geological Storage

-

Saline Aquifers: These porous rock formations, filled with saltwater, are ideal for storing CO2. The CO2 reacts with the minerals in the aquifer over time, forming stable compounds that prevent leakage.

-

Depleted Oil and Gas Fields: These sites have a proven ability to contain substances under pressure, making them suitable for CO2 storage.

Monitoring and Safety

Ensuring the long-term safety of stored CO2 is a critical aspect of carbon sequestration. Advanced monitoring technologies, such as seismic imaging and pressure sensors, are used to track CO2 behavior underground and prevent leaks.

Advantages and Disadvantages of Carbon Capture and Storage

The Benefits of CCS

-

Emission Reduction: CCS can capture up to 90% of CO2 emissions from industrial processes, significantly reducing the carbon footprint of energy-intensive industries.

-

Versatility: Applicable across multiple sectors, including power generation, manufacturing, and even bioenergy, CCS offers a broad range of solutions.

-

Economic Opportunities: The utilization of captured CO2 in products like concrete or fuels creates new markets and drives innovation.

-

Support for Net-Zero Goals: CCS is a vital tool for achieving global climate targets, particularly for sectors where emissions are hard to eliminate.

The Drawbacks of CCS

-

High Costs: The technology remains expensive, with capture costs alone accounting for up to 70% of total expenses.

-

Energy Requirements: CCS systems require significant energy, which can offset some of their carbon-saving benefits.

-

Storage Risks: Although rare, the risk of CO2 leakage from storage sites poses environmental and safety concerns.

-

Delayed Transition: Critics argue that CCS may encourage continued reliance on fossil fuels instead of transitioning to renewable energy sources.

Future Directions for Carbon Capture and Storage

As the world moves toward decarbonization, CCS is poised to play a pivotal role in mitigating climate change. Emerging trends and innovations in the field are addressing current challenges and unlocking new opportunities.

Technological Advancements

-

Direct Air Capture (DAC): This technology captures CO2 directly from the atmosphere, offering a way to address emissions that are already in the air.

-

Improved Capture Efficiency: Innovations in capture materials, such as advanced solvents and membranes, are reducing costs and energy requirements.

-

Digital Monitoring: AI and IoT technologies are enhancing the accuracy and reliability of storage site monitoring, ensuring long-term safety.

Policy and Market Drivers

Supportive policies, such as carbon pricing, tax credits, and international agreements, are crucial for accelerating CCS adoption. With more governments committing to net-zero goals, the demand for CCS technologies is expected to grow, particularly in carbon-intensive industries.

Global Collaboration

International cooperation and knowledge-sharing are essential for scaling CCS globally. By learning from successful projects and investing in shared infrastructure, countries can reduce costs and maximize the impact of CCS on a global scale.