Understanding Industry 4.0 in Automotive

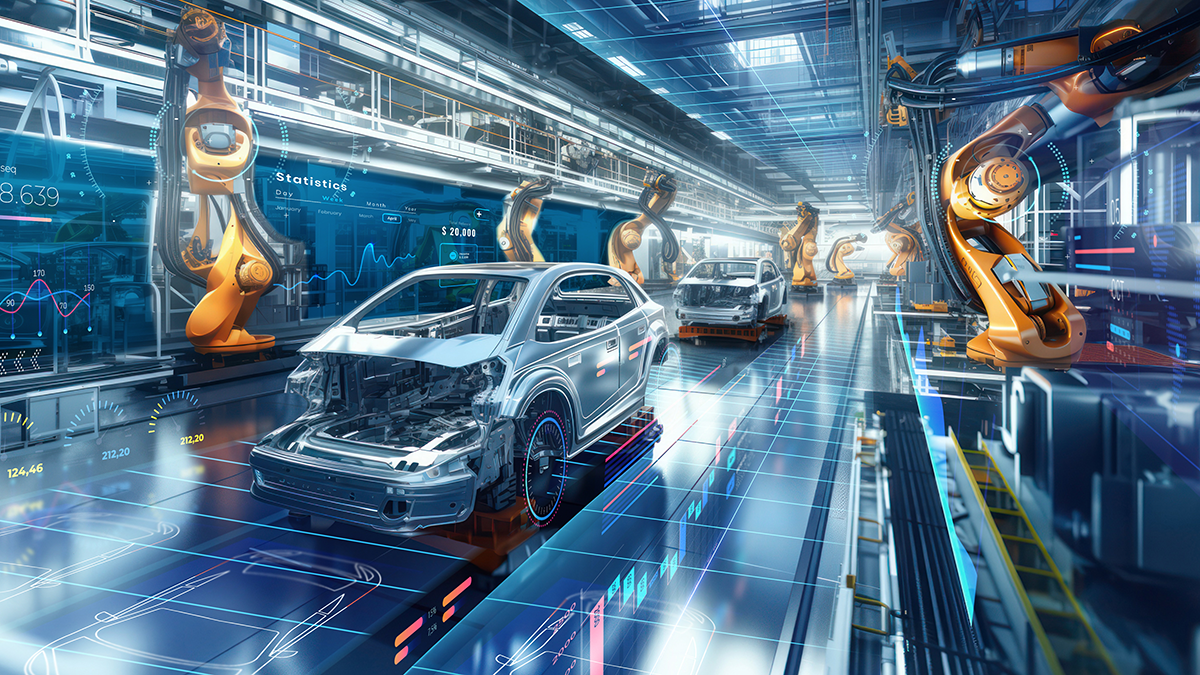

Industry 4.0, often referred to as the fourth industrial revolution, represents a new era of manufacturing that leverages advanced technologies to enhance production processes. In the automotive sector, this transformation is characterized by several key components.

Smart Factories

Smart factories are at the heart of Industry 4.0, featuring interconnected systems that enable real-time data exchange and autonomous decision-making.

-

Automation: Robots and automated systems perform complex tasks with precision and efficiency.

-

Data-Driven Processes: Continuous data collection and analysis optimize production and reduce waste.

-

Interconnectivity: Seamless communication between machines, systems, and humans enhances collaboration and productivity.

IoT Integration

The Internet of Things (IoT) connects various devices and systems, facilitating improved communication and data sharing.

-

Connected Equipment: Sensors and devices gather data on equipment status and performance.

-

Supply Chain Optimization: IoT devices track materials and components, improving inventory management and logistics.

-

Enhanced Product Features: IoT enables smart features in vehicles, such as remote diagnostics and over-the-air updates.

Digital Twin Technology

Digital twins are virtual replicas of physical assets, processes, or systems, used to simulate, analyze, and optimize real-world operations.

-

Design and Testing: Virtual models allow manufacturers to test and refine designs before production.

-

Predictive Maintenance: Digital twins monitor vehicle health and predict maintenance needs, reducing downtime.

-

Process Optimization: Simulations identify bottlenecks and inefficiencies in manufacturing, driving improvements.

Predictive Analytics

Predictive analytics use historical data and machine learning to forecast future outcomes, enabling proactive decision-making.

-

Demand Forecasting: Accurate predictions of consumer demand inform production planning and inventory management.

-

Quality Control: Predictive models identify potential defects, improving product quality and reducing recalls.

-

Cost Optimization: Analytics minimize costs by optimizing resource allocation and energy consumption.

Cyber-Physical Systems

Cyber-physical systems (CPS) integrate physical processes with digital technologies, enhancing control and monitoring capabilities.

-

Real-Time Monitoring: CPS provide real-time visibility into production, enabling swift responses to issues.

-

Autonomous Systems: Self-regulating systems adjust operations based on data inputs, improving efficiency.

-

Safety Enhancements: CPS enhance worker safety through automated monitoring and control systems.

The Benefits of Industry 4.0 in Automotive

Industry 4.0 technologies offer numerous benefits to the automotive industry, driving improvements across various aspects of production and product development.

Increased Efficiency

-

Streamlined Operations: Automation and data-driven processes reduce manual labor and enhance productivity.

-

Reduced Downtime: Predictive maintenance and real-time monitoring prevent equipment failures and production delays.

-

Optimized Supply Chains: IoT and analytics improve logistics, reducing lead times and inventory costs.

Enhanced Flexibility

-

Adaptable Manufacturing: Smart factories quickly adjust to changes in demand or product design.

-

Customization: Manufacturers can offer personalized features and options tailored to individual customer preferences.

-

Scalable Systems: Modular and scalable systems support growth and adaptation to new technologies.

Improved Quality and Safety

-

Consistent Product Quality: Advanced analytics and automated quality control ensure high-quality standards.

-

Enhanced Safety Protocols: Cyber-physical systems monitor safety conditions, protecting workers and equipment.

-

Reduced Recalls: Predictive analytics identify potential defects early, minimizing the risk of recalls.

Sustainability and Environmental Impact

-

Energy Efficiency: IoT and analytics optimize energy use, reducing carbon footprints.

-

Waste Reduction: Data-driven processes identify and eliminate waste, promoting sustainable practices.

-

Lifecycle Management: Digital twins and predictive maintenance extend product lifecycles, reducing environmental impact.

Challenges and Considerations

While Industry 4.0 offers significant advantages, it also presents challenges that automotive manufacturers must address.

Integration Complexity

-

Legacy Systems: Integrating Industry 4.0 technologies with existing infrastructure can be complex and costly.

-

Data Management: Handling vast amounts of data requires robust storage, processing, and security solutions.

-

Interoperability: Ensuring seamless communication between diverse systems and devices is critical.

Cybersecurity Concerns

-

Increased Vulnerability: Greater connectivity and data exchange heighten the risk of cyberattacks.

-

Data Privacy: Protecting sensitive information from unauthorized access is essential.

-

Regulatory Compliance: Adhering to data protection regulations requires ongoing vigilance and adaptation.

Workforce Transformation

-

Skill Gaps: The shift to advanced technologies necessitates reskilling and upskilling of the workforce.

-

Change Management: Managing organizational change and fostering a culture of innovation are vital for successful implementation.

-

Job Displacement: Automation may lead to job displacement, requiring strategies to support affected workers.

Table: Key Components and Benefits of Industry 4.0 in Automotive

|

Component

|

Function

|

Benefits

|

|

Smart Factories

|

Interconnected and automated production

|

Increased efficiency and productivity

|

|

IoT Integration

|

Connects devices and systems

|

Improved communication and data sharing

|

|

Digital Twin Technology

|

Virtual replicas for simulation and analysis

|

Enhanced design, testing, and maintenance

|

|

Predictive Analytics

|

Forecasting and data-driven insights

|

Proactive decision-making and cost optimization

|

|

Cyber-Physical Systems

|

Integrates physical and digital processes

|

Real-time monitoring and autonomous operations

|

Questions and Answers (QA)

Q1: How does Industry 4.0 improve efficiency in automotive manufacturing?

A1: Industry 4.0 enhances efficiency through automation, real-time monitoring, predictive maintenance, and optimized supply chains, reducing manual labor and production delays.

Q2: What role does IoT play in the automotive industry?

A2: IoT connects devices and systems, facilitating data exchange, real-time monitoring, and smart features in vehicles, improving communication and operational efficiency.

Q3: How do digital twins benefit automotive manufacturers?

A3: Digital twins enable virtual testing and design optimization, predictive maintenance, and process improvements, enhancing quality and reducing downtime.

Q4: What are the main cybersecurity challenges in Industry 4.0?

A4: Key challenges include increased vulnerability to cyberattacks, data privacy concerns, and the need for regulatory compliance to protect sensitive information.

Q5: How can manufacturers address workforce challenges in Industry 4.0?

A5: Manufacturers can address workforce challenges by investing in reskilling and upskilling programs, implementing change management strategies, and supporting workers affected by automation.

Industry 4.0 is reshaping the automotive sector, bringing unprecedented efficiency, flexibility, and sustainability to manufacturing processes. As these technologies continue to evolve, they promise to drive innovation and competitiveness, paving the way for a smarter, more connected automotive industry.